In a highly competitive world there is no place for lack of reliability. This is applicable in all fields of economic and social activity. In particular, it acquires greater relevance in the operation of lifting equipment and cargo transportation.

The main function of crane work is the lifting of material loading and unloading. For this, every operator must consider some concepts and guidelines to perform their daily work respecting the standard safety measures.

Main causes that cause accidents

Human failure

If we analyze this cause in particular, we can divide it into three aspects:

a) Poor staff rating

In general, the training of the lifting equipment operators is done through the transmission of knowledge of the oldest operators, and not for that reason more experts. This is the first risk that must be minimized by adding to the practical training, the necessary technical knowledge. In this way, it will be possible to evaluate, from the point of view of safety, the risk situations that are presented to the operator.

b) Incomplete training

The training provided to the operators only meets the requirements of the intrinsic operation of the equipment. The current trend shows that it is essential that the operator has knowledge of fault diagnosis, maintenance, and safety and hygiene, in order to develop preventive activities, which allows him to decide in critical situations.

c) Lack of particular knowledge about lifting operations

Involved actors other than the team itself. It is necessary, then, to have a greater universe of knowledge about other related activities that are developed in the context. For example, the inspection of slings and their use, operations close to power lines (currently fifteen people per electrocution per year by discharge through cranes), signals and, especially, the programming of critical loads. It must be taken into account that a failure or breakage of a sling, which produces as a result

final the overturning of a crane, is cataloged as human failure. This is because the operator must know the status of the lifting accessories.

Mechanical failure

In particular, its occurrence may be due to the following factors:

a) Lack of compliance with the preventive and predictive maintenance program

Although this is not a general issue, it has been possible to observe an important gap in maintenance policies. Currently only corrective maintenance is being carried out.

b) Absence of data and knowledge for maintenance

The lack of repair histories has been verified, and very especially the absence of manuals of the manufacturer that are the ones that provide the information for its correct maintenance.

c) Use of unqualified workshops

The repair of a lifting equipment must result in maintaining the safety conditions with which the equipment was designed. The use of unqualified repair shops puts this situation at risk.

d) Use of equipment of a lot of antiquity

The use of old equipment increases the risks of any operation. This is due, basically, to the possibility of the occurrence of mechanical failures.

Failure of the operation due to the environment

The experiences make operators have to have the training and instructions necessary to assess the risks when the environment is not conducive.

Source:

Los motores eléctricos de baja y media tensión, son parte fundamental de los procesos mineros e industriales, están presentes en cada paso, desde la extracción hasta el despacho de los

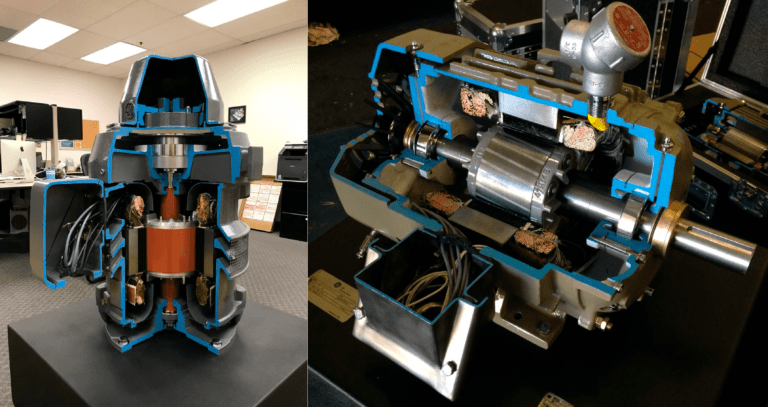

Innovations are made daily in the design of machinery and accessories for the mining activity, looking for improvements in the development of the production process; one of our distributions with the most

La utilización de diversos productos y sustancias en entornos laborales puede conllevar riesgos significativos para la salud, advierte el Ejecutivo de Seguridad y Salud del Reino Unido. Desde el polvo

13775 SW 145 CT Miami FL 33186

+1 (305) 232-2621

info@eymaq.com

Edificio Platinum Plaza Torre B

Andres Reyes 437, Oficina 602

San Isidro, Lima

+51 (1) 640-9811

info@eymaq.com

Calle 138 # 72A – 40

Oficina 404

Bogotá, Colombia

+57 (302) 413-5469

salescolombia@eymaq.com

Rio de Janeiro, Brasil

+1 (786) 589-9884

salesbrazil@eymaq.com